cooling systems

Air2AirTM water-saving technology goes on line at PNM's San Juan station

1 June 2008The US Department of Energy's National Energy Technology Laboratory estimates that US power plant cooling towers evaporate a total of no less than three billion gallons of water each day. A new technology from SPX currently under test at Public Service of New Mexico's San Juan coal fired unit could provide a way of recovering some of this.

SPX has announced that a full-scale cooling tower cell using its patented water saving Marley Air2AirTM technology is now online at Public Service of New Mexico's San Juan generating station in New Mexico.

It will enable the plant to recover approximately 20% of the water it uses for power generation.

This full-scale water conservation test is funded in part by a three-year research grant from the US Department of Energy, National Energy Technology Laboratory.

SPX describes the technology as a "breakthrough water-saving technology for wet cooled power plants."

The Air2AirTM water recovery system enables power plants to recover much of the water evaporated in a standard cooling tower and, in doing so, reduce their annual water consumption by a significant amount.

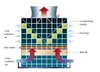

The concept, characterised by SPX as "simple and cost effective," employs a series of PVC heat exchanger packs in the tower plenum area, using cooler, ambient air to condense much of moisture before it exits the tower.

SPX claims the Marley Air2AirTM water recovery system is "the most advanced water-saving solution available for wet cooled power plants."

"It reduces water consumption while maintaining overall steam turbine efficiency," says Tom Dendy, Director of Global Marketing & Development at SPX Thermal Equipment & Services.

"The typical 500 megawatt, coal plant in the US uses roughly 30 000 tons of water each day. A cooling tower fitted with SPX's Marley Air2AirTM technology can reclaim up to 10 000 tons of water each day, or enough to provide 6000 households with water. On an even broader scale, we believe our technology can make a significant contribution to global water conservation efforts."

"In addition to reducing water consumption and treatment costs, coal-fired power plants that utilise SPX's Air2Air water recovery system can achieve greater overall productivity, and even replace more costly means of generating pure water," added Dendy.

"Recovered water can be returned directly to the tower basin, or even piped away as a pure water stream for boiler make-up or other plant uses," he noted.

The performance of the tower and water recovery system at San Juan is being monitored remotely with an ArgusON wireless satellite monitoring and collection system supplied by SPX Flash Technologies. Engineers at SPX Cooling Technologies can continuously monitor the performance and operation of the unit and provide live feedback and operating recommendations to plant operators in New Mexico.

"With the cooperation of PNM and SPX Flash, we are able to closely monitor and validate the performance of the water recovery system," said Glenn Brenneke, Vice President of Research & Development for SPX Thermal Equipment & Services. "This will enable us to collect a complete set of operating data to assess the system over a full range of plant and weather conditions."

SPX's relationship with Public Service of New Mexico dates back to 1975, when the company undertook installation of a wet/dry cooling tower at the San Juan station to address the issue of water availability. Completed in 1978, the tower began commercial operation in 1979.