carbon dioxide germany supplement

RWE: taking the IGCC route to zero emissions

1 December 2006RWE is developing a range of clean coal/lignite technologies, while its longer term hopes are pinned on integrated gasification combined cycle.

Today, nearly 47% of Germany’s power requirements are met from lignite and hard coal based power plants. Even if plans to increase the share of renewables in power generation to 20% by 2020 succeed, the remaining 80% will still have to be covered by conventional sources. This is where clean coal, and clean lignite in particular, can play a key role, RWE believes, alongside nuclear power.

RWE is basically pursuing three lines in its clean coal and lignite development activities:

• Building new higher efficiency lignite and hard coal plants, with retrofit of existing plants.

• R&D aimed at higher efficiency “conventional” steam plants.

• Development of carbon capture and storage (CCS) for conventional plants, as well as IGCC with CCS – the zero CO2 power plant, a “beacon project” which is the centrepiece of RWE’s clean coal activities.

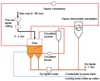

An increase of four percentage points in lignite plant efficiency is being pursued through fluidised-bed lignite drying with internal waste heat utilisation (WTA) technology. The first WTA module is being constructed at the existing Niederaussem BoA plant, replacing 20-30% of the raw lignite input by 2008. The project will cost 50 million euro. In the WTA fluidised bed, run-of-mine lignite is dried at the relatively low temperature of 120°C. The steam produced is used to heat the power plant boiler water, increasing efficiency, rather than being discharged to atmosphere in the flue gas, as in a conventional lignite plant.

WTA has been trialled since 1993 at small scale. It is regarded as a necessary requirement for the lignite fired version of the zero emissions IGCC.

In addition, RWE is engaged in projects to increase steam temperatures, and efficiencies, in coal fired plants. Test sections of superheater pipe have been installed at Esbjerg (DK, hard coal) and Weisweiler (D, lignite). The company is also involved with the COMTES-700 project, including ongoing tests at Scholven (D, hard coal) aiming at 700°C steam. Together with other European operators, RWE is going to perform a pre-engineering study for a subsequent 700°C demonstration plant.

RWE is also investing in the development of improved flue gas scrubbing technologies for post combustion CO2 capture, which is particularly suitable for retrofitting but which, with current techniques, has a big efficiency penalty. Amongst other things, the company is supporting the EU Castor trials at Esbjerg and is also investing around 90 million euros in lignite pilot and demo CO2 scrubbing projects in the Rhenish lignite mining area, with results due in 2012.

However, RWE has strong leanings towards IGCC for new build in the longer term, and is no stranger to the technology. In the 1990s IGCC was the subject of in-depth research in the company. But back then efficiency was the driver, now it is climate protection, as IGCC lends itself to CO2 capture, with less efficiency penalty than some other technologies. With its planned ZEIGCC power plant RWE hopes to attain a net efficiency of 40%, which is far greater than the average for existing pulverised coal plants.

Since the IGCC process produces synthesis gas as an interim product, various chemical products or fuels can be made in addition to electricity. The raw gas with its main components carbon monoxide and hydrogen is the basis both for energy carriers and for basic chemical materials and final products.

Generating hydrogen as an interim product of the zero-CO2 IGCC process opens up the possibility of using it as a fuel in the transport field as an alternative to power generation. The the IGCC power plant can be a starting point for, among other things, methanol and synthetic natural gas (SNG), but also engine fuels like diesel and petrol.

As well as hard coal, lignite is also considered a potential fuel for the ZEIGCC. With the potential conversion of lignite into gas, IGCC technology could be an “interesting option should bottlenecks in oil supplies occur,” RWE says. The lignite deposits in the Rhenish mining area alone, with 50 billion barrels oil equivalent, are roughly comparable with the remaining energy deposits of crude oil and natural gas in the North Sea, it points out.

So, by constructing and operating a large-scale IGCC power plant, RWE believes it will be able to respond flexibly to new market opportunities that go beyond electricity generation.

The choice of gasification technology has yet to be made, contenders including Shell, Siemens Fuel Gasification (formerly Future Energy) - both entrained flow processes - and the HTW fuidised bed process, which is described as a “well proven back up option.” Among future key tasks is showing that the entrained flow technologies will work satisfactorily with lignite.

Clearly a mission-critical issue to be addressed is permanent safe storage of the CO2. It is envisaged that in the ZEIGCC project the separated CO2 will be condensed, liquefied and then transported by pipeline to a geological storage facility, in saline sandstone aquifers. The total storage volume in Germany is estimated to be some 20 billion tons of CO2 (± 8 billion tons). RWE points out that within its RWE Dea subsidiary it has substantial “in-house” expertise on tap in the exploration of oil and gas deposits and in the storage of natural gas and also that in Germany natural gas has been stored in aquifers for over 30 years now. For its ZEIGCC project, the plan is to safely store some 2.3 million tons of CO2 annually and an extensive geological investigation programme has been launched.

RWE’s plan is to have its ZEIGCC plant in operation by 2014, and says it is willing to invest some j1 billion in this “future-geared project.” But if the IGCC power plant is to be commissioned in 2014 the CO2 storage scheme must be pushed forward in parallel and dovetailed technically. Indeed, storage is seen as the biggest technical challenge facing the project.

RWE says that to meet its schedule it will be necessary to “obtain clarity” about the legal framework for CO2 storage. The company says it is willing to bear the high “entrepreneurial risks” but is assuming that the “extraordinary burden” will be recognised within the scope of future trading in CO2 emissions.

Visualisation of WTA lignite drying plant (circled) at Niederaussem Flow diagram of WTA RWE’s ZEIGCC plant Overall concept of the ZEIGCC plant: IGCC plus carbon capture and storage Proposed schedule for RWE’s ZEIGCC project