CARBON DIOXIDE

CASTOR: from pie in the sky to commercial reality

13 July 2004What new technologies are needed to capture CO2 at the post-combustion stage and store it, how can costs be reduced and how can geological storage achieve public acceptance? The CASTOR - CO2 from capture to storage - project aims to answer these questions and to develop and validate the technologies required in real facilities.

The basic aim of CASTOR is to develop the technology that would make possible the capture and geological storage of at least 10% of the CO2 emitted in Europe, which corresponds to about 30% of the CO2 emitted by European power plants and industrial facilities.

To reach this goal, CASTOR aims to improve current techniques and develop, validate and disseminate new concepts for the capture of CO2 and its subsequent secure underground storage. Key targets of the CASTOR project will be:

• A major reduction in post-combustion capture costs, from h50-60 down to h20-30 per ton of CO2 (taking account of the need to treat large volumes of flue gases with low CO2 content and at low pressure).

• Advancement of the general acceptance of the overall concept in terms of storage performance (capacity, CO2 residence time), storage security and environmental acceptability.

• Initiation of the development of an integrated strategy co-ordinating capture, transport and storage options across Europe.

CASTOR will last four years and has been accepted for funding by the European Commission within the 6th European Framework Programme. The total budget is h16 million (with h8.5 million coming from the EU).

A total of 30 partners will carry out the work – R&D institutes, oil & gas companies, power generators and manufacturers – representing 11 European countries.

To demonstrate capture, a pilot plant – the largest such test facility in the world – will be built in an existing coal-fired power station operated by Elsam in Denmark, Esbjerg 3, and will be operated for two years to validate the gas processes developed (in particular new solvents and new membrane contactors).

The work on storage aims at studying new European injection sites and performing risk assessment. An underlying assumption is that public acceptance is a major issue for storage, and this requires proven or highly likely safety – but as yet no generally accepted methodology to predict storage performance (safety) exists.

Post-combustion capture technology

(leader, TNO)

Post-combustion capture is important because of the large fleet of existing plants and boilers, as well as new plants using direct combustion of fuel.

Evaluation of post-combustion capture concepts (membranes, absorption processes, adsorption processes, cryogenics) have identified absorption processes as the most promising, but they are expensive, so the programme focuses on novel technologies that could help form the basis of future business for European companies (which lead in solvent technologies for natural gas but trailing in solvent technologies for flue gas).

The main objectives of work on post-combustion capture (accounting for 65% of the budget) are:

• Development of absorption liquids, with a thermal energy consumption of 2.0 GJ/tonne CO2 at 90% recovery rates.

• Achievement of costs per tonne CO2 avoided not higher than 20 to 30 h/tonne CO2, depending on the type of fuel.

• Carrying out of pilot plant tests showing the reliability and efficiency of the post-combustion capture process.

For post-combustion capture, absorption technology is a leading option but implementation in a power station will decrease the efficiency of generation by 15-25% and increase the power cost by up to 50%. A breakthrough in absorption technology is needed and CASTOR will address the following key issues: energy consumption; reaction rates; contactor improvements; liquid capacities; chemical stability and corrosion; and desorption process improvements.

Work is also needed on better heat integration of CO2 with other process plant, particularly in relation to desorption.

The table below shows how the CASTOR project intends to decrease the costs of capture.

The pilot plant for process integration and validation to be installed at Esbjerg is envisaged to have a capacity of 1 t CO2/hour. It will be operated for at least two years with real flue gas, allowing hands-on experience with absorption technology.

CO2 geological storage performance and risk assessment (leader, SINTEF)

The objective of the storage part of the programme (around 25% of the budget) is to develop and apply a methodology for the selection and the secure management of storage sites by improving assessment methods, defining acceptance criteria, and developing a strategy for safety-focussed, cost-effective site monitoring. The "best practice manual" will be improved by adding four more European facilities, selected to provide a diversity of geological conditions:

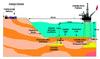

Casablanca oilfield (Spain, operated by Repsol).

The Casablanca oil field is situated off the coast of northeastern Spain. This carbonate oil field at a depth of approximately 2500 m below the sea floor has reached its production tail, and production will soon cease. Repsol is considering using this field for storage of about 500 000 tonnes CO2 per year, which is to be captured at the Tarragona refinery, some 43 km from the field.

Lindach gas field (Austria, operated by Rohoel)

The Lindach gas field is situated in central northern Austria, between Salzburg and Linz. This onshore sandstone gas field, around 850 m below the surface, is almost exhausted. Rohoel AG is considering its transformation into a CO2 storage site and as a possible location for testing the suitability of CO2 injection for enhanced gas recovery. Potential CO2 sources are a paper mill (emitting about 200 000 tonnes CO2 per year) and a fertiliser plant (emitting about 100 000 tonnes CO2 per year). Transport of CO2 may be by trucks. Injection into the field could start towards the end of the CASTOR project period, given positive study results and financing by industrial partners.

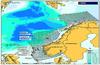

Snøhvit aquifer (Norway, operated by Statoil)

The Snøhvit field is located in the north of the Norwegian Sea. Statoil has got official approval to inject CO2 separated from gas produced from the Snøhvit field into an aquifer (the Tubåen formation) below the reservoir (depth, 2500 m). Injection of 0.75 million t/year is planned to start in late 2006 and will last for more than 20 years.

K12b gas field (The Netherlands, operated by Gaz de France)

The K1 2B gas field is situated off the coast of the Netherlands. Gaz de France has carried out a feasibility study on enhanced gas recovery. Small scale CO2 injection, about 30 000 t/year, was due to start in mid 2004 and large scale injection, about 400 000 t/year, is planned to start in 2006, with a duration of up to 20 years. The reservoir is at 3500-4000 m in Rotliegend clastics (sandstones). A seismic baseline survey exists.

Strategy for CO2 reduction (leader, SINTEF)

Finally, some 10% of the budget will go towards defining the overall strategies required to effect a 10% reduction in EU CO2 emissions and to regularly monitor the effectiveness of the strategies (from capture to storage). The result will essentially be a road map for introducing CO2 sequestration into Europe, and the R&D needed. In addition data will be assembled on capture and geological storage capacities in southern and eastern Europe (an extension of the GESTCO project).

At the same time the legal and public acceptance aspects of CO2 sequestration will be investigated, by developing and applying a template for exploring public perceptions of CO2 storage. A further dimension of the project will be issues arising from EU enlargement.

TablesCASTOR consortium participants Estimation of contributions to capture costs