combined cycle

Fossil fuelled flexibility and EDF’s dash for gas

1 June 2009Flexible fossil generation plays a key role in complementing EDF’s extensive nuclear fleet. In a major move to modernise its fossil fuelled capacity EDF is now in the process of constructing its first combined cycle plants in France.

Within a period of some 20 years, EDF built an unparalleled nuclear power generation fleet – helping to secure France’s energy supplies – producing 87.3% of the mega-utility’s French generated electricity in 2008, with hydro accounting for 9.4%. But EDF also sees fossil generation, accounting for a mere 3.3% (15.8 TWh) of its French generation in 2008, as a key part of the portfolio – indeed essential in providing flexibility and meeting peak demand – and significantly more important than the relatively small percentage would suggest.

In particular, fossil stations enable EDF to constantly adapt production capacity to demand.

Because, relative to nuclear plants, they can start up quickly and modulate their output, coal-fired, oil-fired and gas-fired power stations (plus some hydro stations) are used to generate electricity for semi-baseload and peak load, during periods of high demand, complementing the baseload predominantly provided by the nuclear units (which in France, unusually, do some load following), with the rest of the baseload coming from hydro.

The low variable costs of nuclear and hydro and their limited exposure to fluctuations in the price of hydrocarbons, combined with France’s extensive experience in the design, construction and operation of nuclear power stations, make EDF’s production facilities very competitive. But fossil plants, in addition to their flexibility, also have lower capital costs than nuclear stations and shorter construction times.

The total installed capacity of EDF’s fossil-fired units in France is presently about 12 GWe (with a further 35 GWe of fossil capacity in other countries).

Currently in EDF’s French power plant fleet, coal-fired stations operate for 2500-5000 hours per year, oil-fired stations for 200-1500 hours and simple cycle combustion turbines for several hundred hours.

With an average age of 30 years, and mainly built between the 1950s and 1980s, the EDF French fossil portfolio consists of: 13 coal-fired units (9 x 250 MW and 4 x 600 MW); 11 oil-fired units (4 x 700 MW, 4 x 600 MW and 3 x 250 MW); one gas-fired steam station (120 MW); and ten combustion turbines (simple cycle) (1 x 215 MW, 2 x 185 MW, 3 x 125 MW, 4 x 86 MW).

In recent years, EDF has embarked on an upgrade programme for its most efficient coal-fired power stations, mainly the 600 MW units, improving their environmental performance and extending their lives. Thus the fossil power stations at Cordemais, Le Havre, Blenod and La Maxe will remain in operation until 2015. At the same time, taking account of environmental constraints, the company has decided to phase out the oldest coal and oil fired plants.

In addition the utility decided to bring

2600 MW of oil-fired peak load capacity (mothballed at a time when there was surplus production capacity) back into service: Porcheville, 600 MW in December 2006 and 600 MW in 2008; Cordemais, 700 MW in 2007; and Aramon, 700 MW in 2008.

To cut emissions from its fossil stations EDF has switched to better quality fuel, such as coal with less ash content and oil with low sulphur content. The Porcheville units, for example, now use oil with ultra-low (0.55%) sulphur content.

The three latest 600 MWe coal units have FGD while Cordemais 4 and 5 and Le Havre 4 were retrofitted with SCR - some ten years ahead of the requirements of the LCPD.

Simple and combined cycle units

In June 2007, EDF decided to invest in three new simple cycle combustion turbines for “extreme” peak load service, plus, in a major upgrade of its French fossil fleet, three combined cycle units (adding to an already fairly lengthy list of recent CCGT new build projects in France being undertaken by other developers, see table).

The extreme peak load gas turbines are located in the Ile-de-France region, with a 125 MWe unit at Vitry-sur-Seine (Val de Marne) and two 185 MWe units at Vaires-sur-Marne (Seine-et-Marne). These will bring the extreme peak load capacity, which operates only a few dozen hours per year and can be started up very quickly, taking just 12-20 minutes to reach full power in an emergency, to over 1000 MWe by 2010. In addition three other simple cycle gas turbines, with a total output of 555 MWe, are being built: one on the site of Vaires-sur-Marne and two on the site of Montereau (Seine-et-Marne).

The three new combined cycle units, scheduled to enter service in 2011-2012, are intended to provide semi-baseload duty.

A 460 MW combined cycle unit is being built on the site of the existing power station at Blenod-les-Pont-a-Mousson (Meurthe-et-Moselle), while two of the four 250 MWe oil-fired units at Martigues (Bouches-du-Rhone) - which have a distinguished 35 year track record of bringing security to the French power system, particularly during severe winter peaks - are being repowered and will be transformed into two combined cycle units with a total capacity of 920 MWe.

For all three CCGTs the main equipment suppliers include GE (9FB gas turbine, with DLN2.6+ combustion system)), CMI (HRSG), Emerson (DCS), and Hyundai (main transformer).

While these will be EDF’s first combined cycle units in France they are by no means EDF’s first combined cycle units, and the company can, for example, claim significant experience of CCGT design, construction and operation via several projects implemented between 1999 and 2005 in Mexico, Vietnam and Brazil. In parallel with the French CCGTs EDF is also simultaneously managing the design and construction of the three-unit 1300 MWe West Burton combined cycle plant in the UK.

Repowering Martigues

The new Martigues combined cycle units (Martigues 5 and 6) are each rated at 460 MWe, including 40 MWe from duct-firing in the horizontal HRSGs. Net efficiency will be 56%.

The repowering project will make use of the four-casing 250 MW Rateau-Schneider steam turbines originally installed in Martigues 3 and 4, suitably upgraded and retrofitted for combined cycle use. The steam turbines are oversized relative to the energy in the GT exhausts, hence the duct firing. The original steam turbines of units 3 and 4 had accumulated 85000 and 51000 operating hours, respectively, at baseload conditions. The extensive upgrade will significantly extend their life, with up to 100000 operating hours and 5000 starts allowed for over the next 25 years.

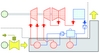

The combined cycle configuration will be multi shaft, with a three presssure and reheat steam bottoming cycle.

EDF is acting as architect engineer (very beneficial in a repowering project of this type because of its intimate knowledge of the existing units).

In operation the Martigues combined cycle units are expected to be dedicated to cyclic operation, with frequent starts and stops, perhaps daily, and wide load variations. This has been a key focus of EDF’s combined cycle design efforts.